Infrastructure

Design:

The company has in-house research & development as well as designing facility equipped with latest CAD/CAM technology and specifically customized technology such as Elecdes, Pro-E, Solid Edge, Primavera, AP100, Biloma & ESMS.

Our engineers are continuously trained by OEMS on their latest offerings that can be incorporated in our solution offers to make it most optimum and user friendly. There is a special focus on designing future ready communicable and smart products which can assist the customers in analyzing their energy consumption trends.

Manufacturing:

After procuring a job, completion of engineering and design and finalizing a BOM, a serial number is generated. Our production team works based on this serial number. The usual time for procurement of material is 3-5 weeks, our purchase team uses the BOM in the serial number to generate a PO and start buying switch gear and non-switch gear items. Exactly 1 week before procurement of materials, our Fabrication team beings working on the panels listed in the serial number. Base plates are cut at first to allow fitting and wiring of material. In an ideal situation, after fabrication and bolting, the panel body should be ready at the same time as the base plates are wired. Our factory is a 5 story building with the floors being divided into various sections of works to complete stages and finish our product.

1st floor – CNC machine : Cutting/Punching/Bending

After moving items up after fabrication, the product moved down floor by floor

1st floor – Packing and loading dock for dispatch

2nd floor – Finishing work/ testing / internal and client inspections

3rd floor – Busbar and wiring floor

4th floor – Bolting and panel

5th floor – Powder coating unit : 10 tank process and paint

CNC Machine (Fabrication)

- First we cut and punch the base plates so fitting and wiring work can begin

- We then cut the posts, and other internal sheets

- We then complete bending of these items

- We then send them up for welding if required and then to the powder coating unit via an elevator

- We then cut the top, side covers and doors (these items are only required once the panel is on the third floor (once base plates are fitted in and wiring of items on doors can begin)

Powder coating unit

- Items are treated in the 10 tank process

- Then depending on the requirement, we usually spray paint and send in either our heat chamber or electrical chamber

- We then pass them through tests to see if the paint job is acceptable

Bolting and Assembly

- Depending on the design, we have various methods and systems of how we ready our team

- Items that are usual items that can be used universally for our jobs are stored neatly on racks

- All machinery is checked on regular basis and safety measures are followed

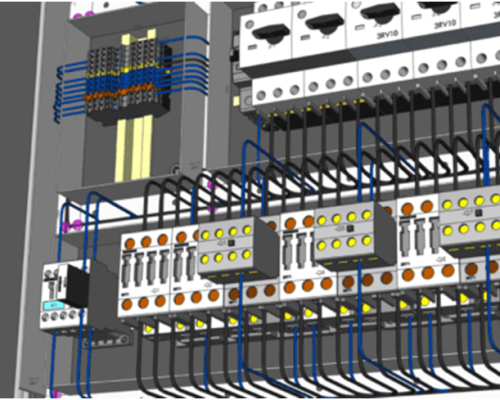

Fitting/ Busbar/ Wiring

- Busbar cutting and sleeving begins during our bolting stage, based on the serial number, our busbar designs are notified which panels they need to work on, and they start to give designs to operate the busbar cutting/punching and bending machines.

- Wiring also begins once fitting materials is completed on the base plates, while busbar is being cut

- Once bolting is complete, busbar is ready and so are wired base plated

- We then begin busbar assembly, install the base plated and begin to assemble the doors

• We then make the connects as required, based on drawings issued to the floor as well as job super wiser

Quality:

Our Commitment to Quality

EAP believes in delivering quality product and services on time, at a competitive price adhering to customer specifications. We believe in long term relationships and total customer satisfaction.

Quality is the utmost thing to be achieved in every business. It’s the result of continuous up-gradation of manufacturing process and its practices with innovative ideas

This being the general philosophy of our firm, the function of Quality Assurance is to act as a motivator towards improvising on these twin aspects of sustain and promote Quality in our firm by means of our products.

FUNCTIONS

► To prepare Operational Procedures for the accomplishment of every action and endeavour by each department and also for the periodical reviewing and updating of procedure.

► To convey the importance and requirement of quality and eminence of high quality products to concerned staff to be able to achieve production / procurement /quality control by associated methods.

► To furnish Production and Inspection procedures.

► Vendor Evaluation.

► Periodic assessment of work done by the employees of different departments.

Also at every stage of manufacturing the quality of the product is taken up as the most essential piece of work right from selection of sheets, Shearing, folding, welding, drilling, punching, surface cleaning, powder coating and essential quality checks are regularly made along with the routine checks like HV Test, dielectric strength, Megger test etc. are addressed stringently and sincerely to climate all sorts of errors.

“We in EAP are committed to being a customer-Oriented organisation where quality is the inspiration and innovation is the way of life”

Makes:

EAP uses the most Trusted Vendors for Raw materials – This changes based on requirements and project specifications, however these are our standard approved make list.

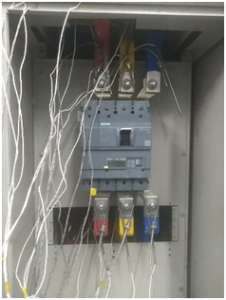

Testing:

After completion of work via drawings, we use our equipment which is stored in testing lab neatly and our engineers follow our QAP and complete routine tests. We also perform any tests if specially required by a specific client.

4000A 3 phase Current Injection Kit

630 A Temp rise test in our test lab

Our Test labs

Our Testing Equipment